STERILE FLUIDS ENGINEERING & KNOW HOW

In the past we actively participated in the implementation, design, procurement, construction and startup of various IV fluids facilities including Know how and technological transfer, with personnel training and technical as well as Pharmaceutical Know How assistance for new facilities build in North Africa, Middle East and Far East.

Including sales and marketing introducing in the first phase new products to the markets, while transitioning to locally manufactured products.

Today we provide engineering and know-how for IV facilities up grades, as well as technical assistance in the design specifications and main equipment selection based on the market needs.

Personnel training and regulatory assistance in preparation of registrations files for selected IV solutions.

Sales and Marketing, assistance in market assessment to decided which products should be considered viable for the new project and demanded by the local or export markets.

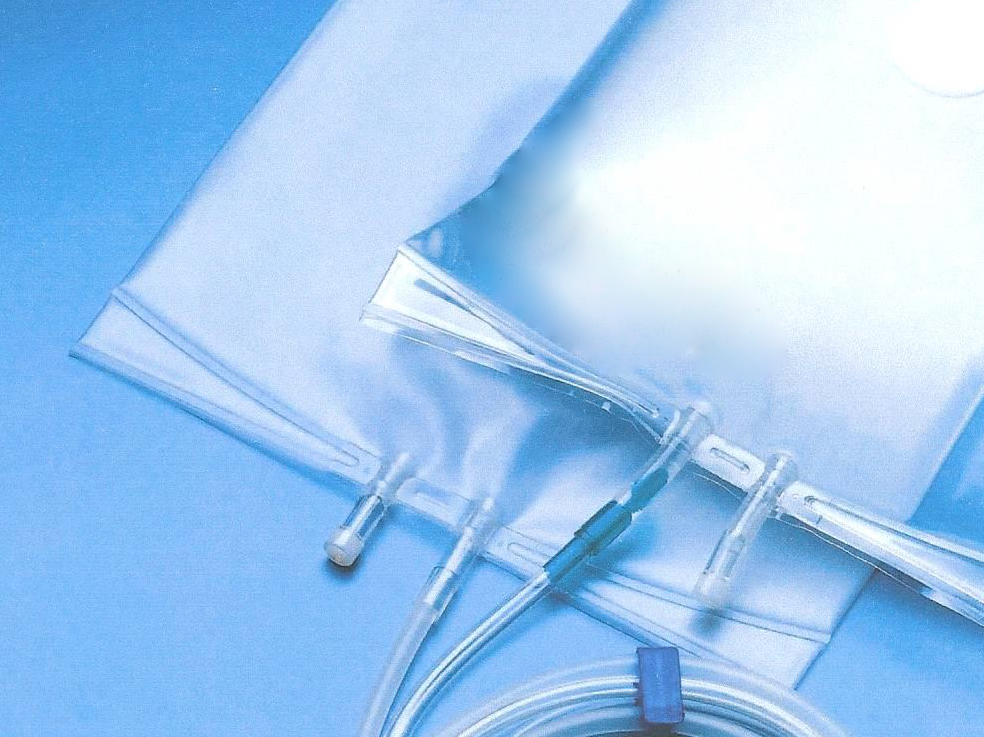

Our experience is in soft bags in PP (polyolefins), for this we concentrated our efforts to develop and build our own equipment’s for automated production of PP bags as well as IV’s filling machines